Tool presetter

Tool presetter

HP-6040V-FA

Automatic measuring system(With cutting tool replacement unit)

Component part

- プリセッタ「HP-6040V」

- 登録されている測定プログラムに従い、工具径や工具長、振れ、形状、刃先摩耗を全自動で測定します。

- 第2カメラは工具ID(二次元コード)の読み取りと刃先形状の確認に使用します。

- 第2カメラは90°旋回できるので刃物上部からの刃先形状確認もできます。

- 締緩装置

- コレットチャックやミーリングチャック等の刃具を自動交換するユニットです。

- データベースの工具情報(ナット位置、設定トルク)で、自動的にナット位置まで爪が移動し、最適トルクでナットを締め付けます。

- 工具/ツーリング置台

- 多関節ロボットで工具/ツーリングを取り出します。

- 台車やパレットを利用することも可能です。

- ホルダ清掃ユニット

- 回転機構が付いていて、プリセッタに装着する前にホルダのテーパ部に付着したクーラントや埃などの汚れ、異物を除去します。

- スピンドル・クリーナー

- プリセッタのスピンドルに付着した汚れ、異物を定期的に除去します。

- 多関節ロボット

- プリセッタへのツーリング搬送や工具の着脱、クリーニング作業などシステム内のすべての搬送を行います。

- 複合ハンドで、工具とツーリングの両方を掴むことができます。

- ツールチェンジャを利用しハンドを交換することで、異なる主軸サイズもにも対応できます。

- タッチパネルモニタ

- 全自動計測システムの工程を表示します。

- 測定結果やOK/NGの判定を表示します。

Spec

| Measuring motion method | Electrical control |

|---|---|

| Measuring range | Length direction(Z axis):50 ~ 600mm Radial direction(X axis):-Φ50 ~ Φ400mm |

| Min value of counter reading | Length direction(Z axis):0.001mm Radial direction(X axis):Φ0.002mm |

| Air supply | 0.4MPa(4kgf/cm2) |

| Camera pixels | Approx 20K |

| Real viewing field | 5×7mm |

| Attach and release | Air |

| Power supply | AC100V |

| Weight | 400kg |

| Shank size | BT50, BT40, BT30, 25T, S20T, HSKA125, HSKA100, HSKA63, HSKA50, HSKA40, HSKA32(HSK32 is only for tools other than center-through type) Choose one shank from the size list above,if it is BT shank,please check the type of stud bolt. |

| Standard bar(Wooden box) | Shank size: 1piece If it is BT shank,please check the type of stud bolt. Stud bolt is prvoided for BT shank only. Please designate the stud bolt type. |

|---|---|

| Cover | 1pcs each for Spindle, Machine body, Screen |

| Quick sleeve | BT or HSK Corresponding to various size(please check the tool shank size) |

|---|---|

| Tool manager | A system that transfer the necessary tool date to machining center directly during the processing. Detailed specifications need to be negotiated separately. |

| Tool management database | Logging in,reading and calling out the tool information. |

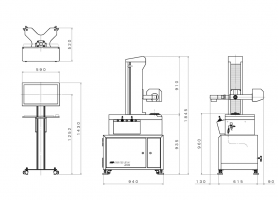

Dimensions

zoom

zoom